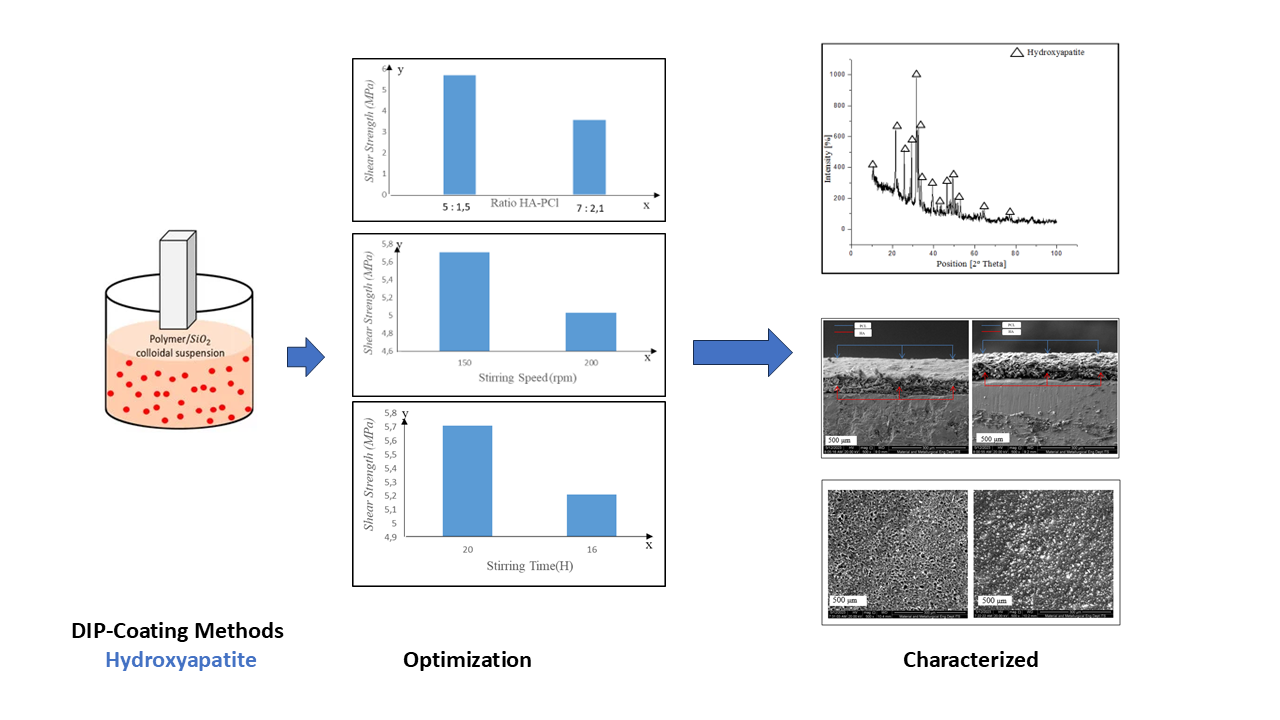

Hydroxyapatite-Polycaprolactone Coating on 316L Stainless Steel Surface Using Dip Coating Method

DOI:

https://doi.org/10.22437/chp.v8i2.30842Keywords:

Empirical Model, Hydroxyapatite-Polycaprolactone, Stainless Steel 316LAbstract

Stainless steel 316L is a metal that can be used for bone implants but exhibits low biocompatibility. The low biocompatibility can lead to inflammation, infection, or rejection within the body's tissue system. It is coated with hydroxyapatite-polycaprolactone to enhance the biocompatibility of stainless steel 316L. This study aims to examine the effects of stirring time, stirring speed, and the appropriate hydroxyapatite-polycaprolactone ratio on the shear strength of hydroxyapatite-polycaprolactone using the dip coating method and to determine the empirical model for the resulting shear strength of the hydroxyapatite-polycaprolactone layer. Hydroxyapatite and polycaprolactone were mixed using acetone and stirred at a speed of 150 rpm for 20 hours. Then, the stainless steel 316L substrate was immersed in the suspension and dried at 56°C for 1 hour. The process conditions optimization in this study employed a 2k modeling approach. The empirical shear strength model in this research is represented as y = -216.9 + 36.42A + 1.426B + 14.43C - 0.2345AB - 2.380AC - 0.08943BC + 0.01468AB*C, with an R2 value of 0.99. The variables with the most significant influence on shear strength, ranked from largest to smallest, are the HA-PCl ratio (A), followed by the two-way interaction between the HA-PCl ratio (A) and stirring speed (B), the three-way interaction between the HA-PCl ratio (A), stirring speed (B), and stirring time (C), followed by the two-way interaction between the HA-PCl ratio (A) and stirring time (C), stirring time (C), stirring speed (B), and the two-way interaction between stirring speed (B) and stirring time (C). The highest shear strength of the hydroxyapatite layer was achieved at a HA-PCl ratio of 5:1.5, stirring speed of 150 rpm, and stirring time of 20 hours, with a value of 5.71 MPa

Downloads

References

1. Shi H, Zhou Z, Li W, Fan Y, Li Z, Wei J. Hydroxyapatite based materials for bone tissue engineering: A brief and comprehensive introduction. Crystals. 2021;11(2):1-18. doi:10.3390/cryst11020149

2. Ielo I, Calabrese G, De Luca G, Conoci S. Recent Advances in Hydroxyapatite-Based Biocomposites for Bone Tissue Regeneration in Orthopedics. Int J Mol Sci. 2022;23(17). doi:10.3390/ijms23179721

3. Mishchenko O, Yanovska A, Kosinov O, et al. Synthetic Calcium–Phosphate Materials for Bone Grafting. Polymers (Basel). 2023;15(18):1-49. doi:10.3390/polym15183822

4. Im K hyeong, Kim M chul, Kang D kuk, Kim K nam, Kim K mahn, Lee Y keun. Hydroxyapatite / Titania Hybrid Coatings on Titanium by Sol-Gel Process. Biomater Res. 2006;10:224-230.

5. Safavi MS, Walsh FC, Surmeneva MA, Surmenev RA, Khalil-Allafi J. Electrodeposited hydroxyapatite-based biocoatings: Recent progress and future challenges. Coatings. 2021;11(1):1-62. doi:10.3390/coatings11010110

6. Mondal S, Park S, Choi J, et al. Hydroxyapatite: A journey from biomaterials to advanced functional materials. Adv Colloid Interface Sci. 2023;321(October):103013. doi:10.1016/j.cis.2023.103013

7. Negaresh M, Javadi A, Garmabi H. Poly(lactic acid)/ poly(ε-caprolactone) blends: the effect of nanocalcium carbonate and glycidyl methacrylate on interfacial characteristics. Front Mater. 2024;11(March):1-15. doi:10.3389/fmats.2024.1377340

8. Sivalingam G, Vijayalakshmi SP, Madras G. Enzymatic and thermal degradation of poly(ε-caprolactone), poly(D,L-lactide), and their blends. Ind Eng Chem Res. 2004;43(24):7702-7709. doi:10.1021/ie049589r

9. Blackwell CJ, Haernvall K, Guebitz GM, Groombridge M, Gonzales D, Khosravi E. Enzymatic degradation of star poly(ε-caprolactone) with different central units. Polymers (Basel). 2018;10(11):1-15. doi:10.3390/polym10111266

10. Ali Akbari Ghavimi S, Ebrahimzadeh MH, Solati-Hashjin M, Abu Osman NA. Polycaprolactone/starch composite: Fabrication, structure, properties, and applications. J Biomed Mater Res - Part A. 2015;103(7):2482-2498. doi:10.1002/jbm.a.35371

11. Economy C, Single-use S. Polylactic Acid / Polycaprolactone Blends : On the Path. 2020;(2017):1-18.

12. Murugan N, Murugan C, Sundramoorthy AK. In vitro and in vivo characterization of mineralized hydroxyapatite/polycaprolactone-graphene oxide based bioactive multifunctional coating on Ti alloy for bone implant applications. Arab J Chem. 2018;11(6):959-969. doi:10.1016/j.arabjc.2018.03.020

13. Kannan S, Balamurugan A, Rajeswari S. H2SO4 as a passivating medium on the 119

Chempublish Journal, 8(2) 2024, 109-119

localised corrosion resistance of surgical 316L SS metallic implant and its effect on hydroxyapatite coatings. Electrochim Acta. 2004;49(15):2395-2403. doi:10.1016/j.electacta.2004.01.003

14. Fadli A, Yenti SR, Huda F, Prabowo A, Marbun UN. Empirical Model to Predict the Hydroxyapatite Thickness on the Surface 0f 316L Stainless Steel by The DIP Coating Method. Ceram - Silikaty. 2021;65(4):386-394. doi:10.13168/cs.2021.0041

15. Heidari L, Tangestani A, Hadianfard MJ, Vashaee D, Tayebi L. Effect of fabrication method on the structure and properties of a nanostructured nickel-free stainless steel. Adv Powder Technol. 2020;31(8):3408-3419. doi:10.1016/j.apt.2020.06.025

16. Hernández-Silva E, Vázquez-Hernández F, Mendoza-Acevedo S, et al. Effect of stirring rate on the size of hydroxyapatite nanoparticles synthesized by a modified heat-treated precipitation method. Process Appl Ceram. 2023;17(2):133-139. doi:10.2298/PAC2302133H

17. Salimi MN, Bridson RH, Grover LM, Leeke GA. Effect of processing conditions on the formation of hydroxyapatite nanoparticles. Powder Technol. 2012;218:109-118. doi:10.1016/j.powtec.2011.11.049

18. Bintoro, Azis Y, Akbar F. Pengaruh Kecepatan Pengadukan Terhadap Kinetika Reaksi Pembentukan Hidroksiapatit (HAp) dari Precipitated Calcium Carbonate (PCC) Cangkang Telur Itik Melalui Proses Presipitasi. Jom FTEKNIK. 2018;5(2):2-6.

19. Hidayah PH, Fadli A, Amri A. Pelapisan Hidroksiapatit pada Stainless Steel 316L menggunakan Metode DIP Coating dengan Variasi Rasio Binder Pati Sagu dan Waktu Pengadukan. Jom FTEKNIK Vol. 2016;3(1):1-7. http://117.74.115.107/index.php/jemasi/article/view/537

20. Zhi C, Wu Z, Ma L, et al. Effect of thickness ratio on interfacial structure and mechanical properties of Mg/Al composite plates in differential temperature asymmetrical rolling. J Mater Res Technol. 2023;24:8332-8347. doi:10.1016/j.jmrt.2023.05.031

21. Mohd Yusoff MF, Abdul Kadir MR, Iqbal N, Hassan MA, Hussain R. Dipcoating of poly (ε-caprolactone)/hydroxyapatite composite coating on Ti6Al4V for enhanced corrosion protection. Surf Coatings Technol. 2014;245:102-107. doi:10.1016/j.surfcoat.2014.02.048

22. Wong SC, Baji A, Gent AN. Effect of specimen thickness on fracture toughness and adhesive properties of hydroxyapatite-filled polycaprolactone. Compos Part A Appl Sci Manuf. 2008;39(4):579-587. doi:10.1016/j.compositesa.2007.09.004

23. Bunaciu AA, Udriştioiu E gabriela, Aboul-Enein HY. X-Ray Diffraction: Instrumentation and Applications. Crit Rev Anal Chem. 2015;45(4):289-299. doi:10.1080/10408347.2014.949616

24. Aminatun, Hikmawati D, Yasin M. The effect of sintering temperature to the quality of hydroxyapatite coating on cobalt alloys as the candidate of bone implant prosthesis. J Biomimetics, Biomater Biomed Eng. 2017;32:59-68. doi:10.4028/www.scientific.net/JBBBE.32.59